High Efficient Competitive Price Tire Recycling Pyrolysis Equipment for Sale

Overview Package size per unit product 11.80cm * 2.13cm * 2.72cm Gross weight per unit product 50000.000kg high efficien;

Basic Info

| Certification | CE, ISO |

| Structure | Horizontal |

| Equipment | Pyrolysis Machine |

| Inputs | 2-15 Tons Per Day |

| Type | Tire Pyrolysis Machine to Oil |

| Structural Form | Horizontal Form |

| Reactor Material | Q345r |

| Warranty of Reactor | 18 Months |

| Raw Material 1 | Waste Plastic, Tires, Rubber, Aluminum Foil |

| Final Product 1 | Oil, Carbon Black |

| Raw Material 2 | PMMA |

| Final Product 2 | Crude MMA |

| Raw Material 3 | Oil Sands, Oil Sludge, Waste Oil |

| Final Product 3 | Oil, Carbon Residue |

| Installation Type | Field Installation, Skid Mounted |

| Shipping Type | Ocean Shipping, Land Shipping |

| Packing | Naked |

| Transport Package | Naked |

| Specification | Based on the order |

| Trademark | / |

| Origin | Henan, China |

| Production Capacity | 20 Set/Sets Per Month |

Packaging & Delivery

Package size per unit product 11.80cm * 2.13cm * 2.72cm Gross weight per unit product 50000.000kgProduct Description

high efficient competitive price tire recycling pyrolysis equipment for sale

Product Description

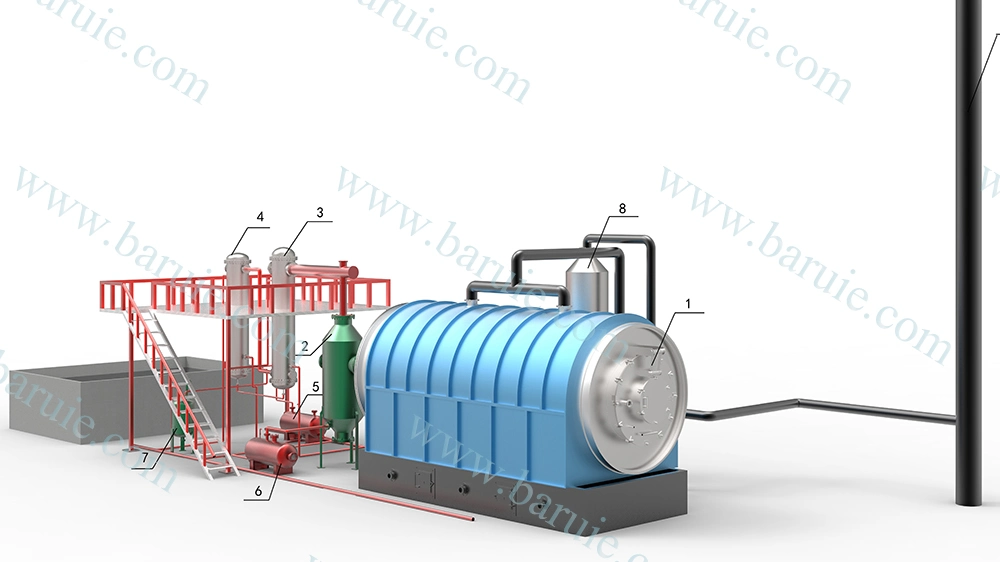

Pyrolysis equipment --- is Henan BARUi Environmental Protection Equipment resources recycling project which using the waste tires, waste rubber, waste plastic, PMMA, aluminum foil, aluminum plastic and other organic solid waste as raw material, adopt pyrolysis process to fuel oil.Compared with the burning or landfill, solve the waste problem by pyrolysis technology is more acceptable by people in the world, because it is fully environmentall and can bring investors high profit.

Basic Information

Material of equipment | Q345R for reactor,Q245B for other devices |

Power | Depending on specific configuration |

Voltage | It can be customized according to your requirement |

Raw Material | Waste plastic, waste tire, rubber, PMMA, oil sludge, aluminum foil |

Final Product | Oil, residue, gas |

Color of equipment | As required |

ReactorOne 10ton capacity Pyrolysis reactor size is 2800*6600mm , it is made of Q345R boiler steel plate , which can resistance highpressure and temperature , its thickness is 16mm/18mm that can be customized.

The baseIt is also a burning room, under the reactor, where fuel is burned to heat the reactor. The burning room is slightly different with different fuels.

Condenser and Oil receiverFor larger capacity, we recommend locally installation type. In this way, there is enough distance between the device for devicemaintenance.The tubular condenser can contact the oil gas to the greatest extent to liquefy the oil gas, so as to maximize the oil yieldTwo 2.5m3 oil tanks, so you don't have to worry too much in the whole process.The dedusting systemDedusters to remove the dust and sulphur content effectively , the ceramic packing is speically used to filter the dust and thealkaline water spray nozzle to remove the acidity, finally no black smoke emitted.

Certifications

More detailed information

Contact me or leave your contact information for more detailed information. We will reply you asap.

You may also like

Send inquiry

Send now